Metals

Titanium

Based on its many advanced applications in everything from aerospace to the marine and medical fields, it would be easy to consider titanium as a futuristic metal. That’s why many are surprised to learn that the world’s 4th most abundant metallic element was actually used in dentistry as early as the 1940s. Titanium is also found in meteors as well as both the Moon and certain stars.

Inductotherm Group companies around the world are expert in the thermal processing of titanium, frequently using the Vacuum Arc Remelting (VAR) systems engineered under the Consarc name, one of Inductotherm Group’s ten global brands. We support multiple customers who use titanium in the manufacture of a wide list of products, including everything from high-end golf clubs to multiple medical products such as prosthetics, inner body devices and more.

Related Resources

Select a Process

Rail and Mill Roll Hardening

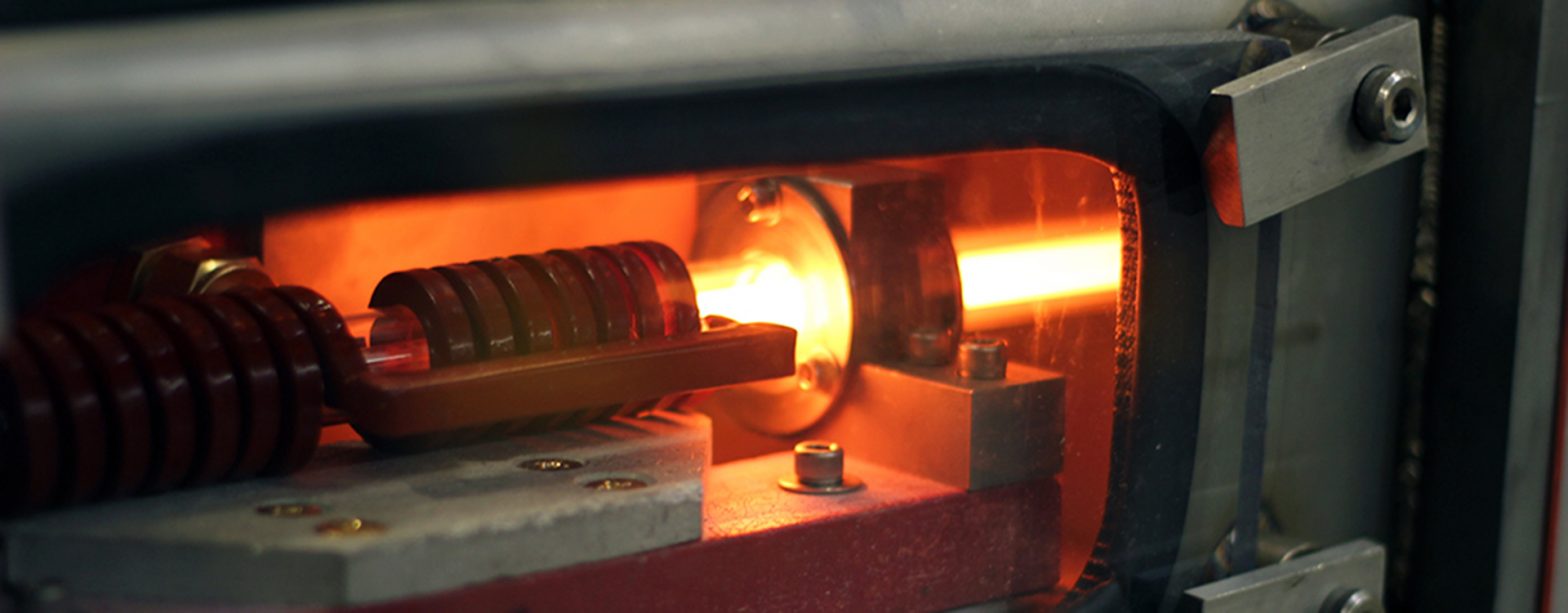

Mill Roll Hardening Systems are becoming increasingly popular with the expanding development of cold mills which subject the rolls to high stresses. For the surface heating of steel parts, induction heating is considered to be the application best suited for this. Induction heating has many applications and is especially effective in hardening rolling mill rolls. Railhttps://www.inductothermgroup.com/products/rail-and-mill-roll-hardening/...

LEARN MORE »

Slab, Bloom and Transfer Bar Heaters

Our high-power density Slab, Bloom and Transfer Bar Heaters provide efficient and cost-effective technologies to bring surfaces to the optimal temperatures required for forming, rolling or forging. Metals which are susceptible to oxidation and scale formation such as titanium, if heated above certain temperatures, can be accurately heated using induction heating, thus increasing yield andhttps://www.inductothermgroup.com/products/slab-bloom-and-transfer-bar-heaters/...

LEARN MORE »

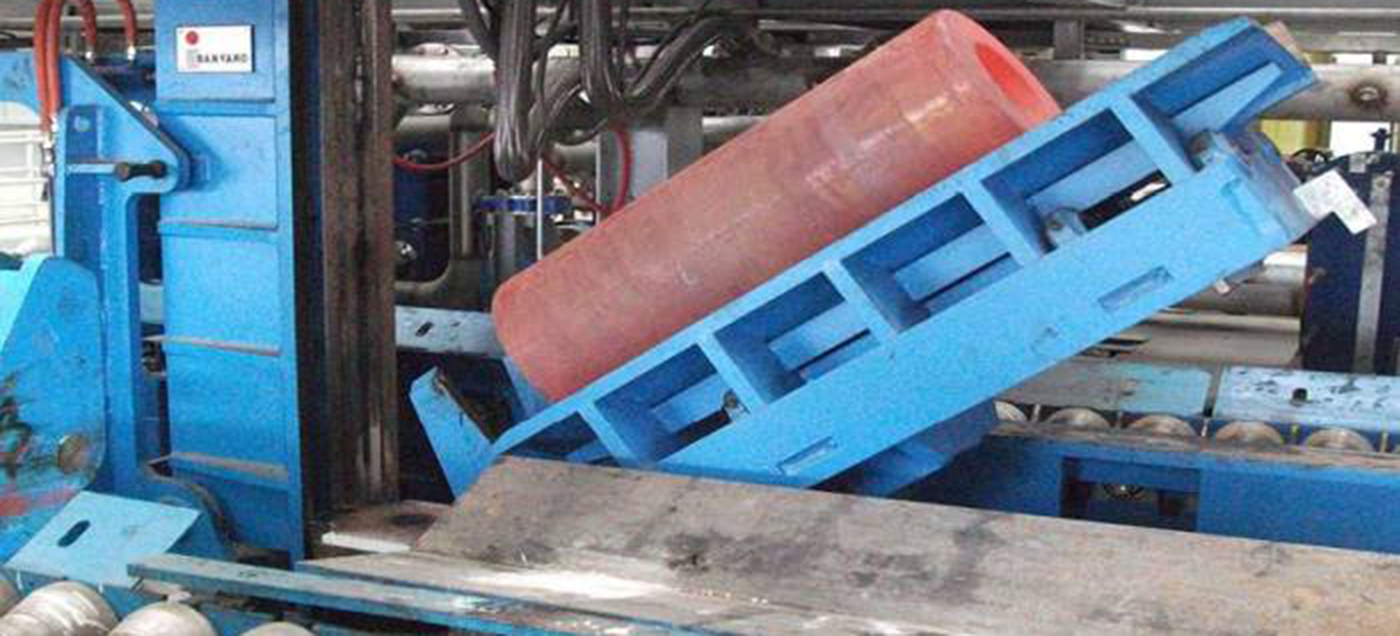

Vertical Billet Heaters

Banyard Vertical Steel Induction (VSI) systems have been designed for the precise vertical induction heating of solid or pierced billets and tubes. These systems heat billet diameters from 150mm to 460mm, and lengths from 300mm to 1500mm. Benefits include better temperature distribution, ability to vary the temperature profile along the billet length, and no billethttps://www.inductothermgroup.com/products/vertical-billet-heaters/...

LEARN MORE »

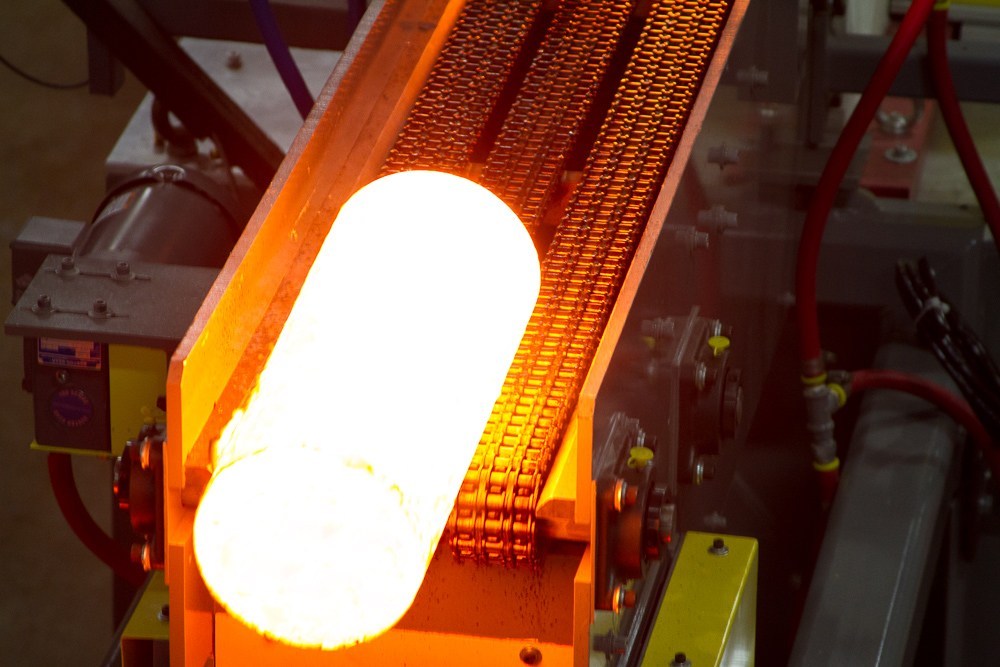

Modular Induction Billet Heating Systems

Inductotherm Group companies manufacture the InductoForge® modular billet heater, the latest design in a generation of industrially-proven systems, built to thrive in aggressive forging environments. The InductoForge® heater features the IHAZ™ Temperature Profile Modeling computer program, designed to identify and store an advanced temperature control best-suited to each application. Inductotherm Group companies also manufacture InductoForgehttps://www.inductothermgroup.com/products/modular-induction-billet-heating-systems/...

LEARN MORE »

Modular Induction Bar Heating Systems

Inductoforge® modular bar heaters are revolutionary products for the forging industry. The flexible modular design allows the forge shop to assemble an induction system that exactly matches its application requirements. The powerful combination of advanced engineering, product innovation and over 55 years of experience in induction heating has made Inductoforge® systems the world leader inhttps://www.inductothermgroup.com/products/modular-induction-bar-heating-systems/...

LEARN MORE »

Vacuum Heat Treatment and Brazing Furnaces (VHT)

Vacuum heat treatment is a well-established practice in the aerospace (both OEM and repair), land-based turbine, automotive and tool industries. Controlled thermal processing of components is carried out in a vacuum environment to eliminate the deleterious effects of the charge reacting with the gases present in the air....

LEARN MORE »

General Heat Treat Systems

Radyne brand heat treatment systems offer flexible, robust induction heat treating that can be effortlessly integrated into your production ecosystem. Radyne heat treat systems include a full line of scanners and pop-ups to handle large and small parts, from parts under an ounce and shorter than an inch to parts over 5000 lbs. in weighthttps://www.inductothermgroup.com/products/general-heat-treat-systems/...

LEARN MORE »

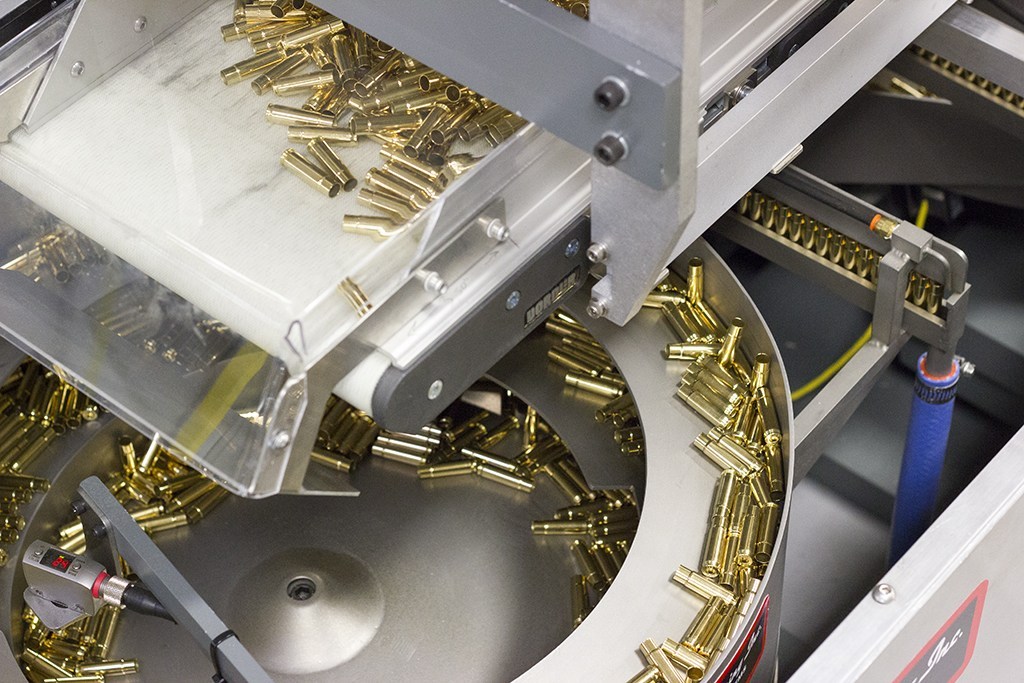

Munitions and Ammunition Annealing and Bonding Systems

Radyne brand ammunition annealing and bonding systems are used to make bullets for law enforcement and military applications, as well as for the hunting and shooting enthusiast. Radyne brand has a well-established history of designing induction heating equipment that is used for heat treating and forming shells to create specialized fragmentation patterns, penetrating characteristics, andhttps://www.inductothermgroup.com/products/munitions-and-ammunition-annealing-and-bonding-systems/...

LEARN MORE »

Heat Treat Systems (All Automotive Components)

Many metals require heating and/or heat treating to achieve their optimum physical properties. Inductoheat brand equipment leads the market in quality heating and heat treating with flexible and innovative systems that are designed and built for long-life performance. Inductotherm Group companies’ heat treating equipment gives you the most flexible heat treating solutions, engineered for today’shttps://www.inductothermgroup.com/products/heat-treat-systems-all-automotive-components/...

LEARN MORE »

Induction Bar Heaters

Inductoheat® induction bar-end heating equipment is available for many sizes and shapes of parts. Multiple bar ends can be heated using differing types of induction coils. The powerful combination of advanced engineering, product innovation and over 55 years experience in induction heating has made Inductoheat® brand equipment the leader in billet and bar heating equipment....

LEARN MORE »

Induction Scanners

Inductotherm Group companies all over the world manufacture Inductoscan® brand induction scanning systems for scanning, rotary table heating and large part hardening. The modular heating systems’ unique design allows for a wide range of power supplies, controls and components to be integrated within a common base to better match current production needs. It can behttps://www.inductothermgroup.com/products/induction-scanners/...

LEARN MORE »

ARMS® (Automated Robotic Melt Shop Systems)

Inductotherm Group companies are the first to develop and manufacture an innovative automated robotic melt shop system, called the ARMS™ System. The ARMS System replaces the furnace operator on the open melt deck with a foundry robot that has integrated charging, slag removal, tool handling and remote viewing systems. This allows the furnace operator tohttps://www.inductothermgroup.com/products/arms-automated-robotic-melt-shop-systems/...

LEARN MORE »

Automated Pouring Systems

Inductotherm brand automated pouring systems for foundries and melt shops are designed for maximum productivity. They provide the higher levels of pouring accuracy required to eliminate quality robbing under-pours and metal wasting over-pours....

LEARN MORE »

Induction Holding Furnaces

Inductotherm Group companies manufacture two types of advanced holding systems: Channel furnaces and Mini-Heel™ furnaces. Both offer true volume flexibility for continuous and batch duplexing, and can maintain a continuous supply of metal ready to pour 24 hours a day, 7 days a week....

LEARN MORE »

Induction Melting Furnaces

Inductotherm brand coreless melting furnaces provide superior performance and outstanding durability for all your melt shop needs, regardless of the size of your foundry. Inductotherm Group companies offer a range of furnace sizes from small induction melting furnaces that meet the demanding requirements of investment casters, specialty foundries and the precious metals industry, to heavyhttps://www.inductothermgroup.com/products/induction-melting-furnaces/...

LEARN MORE »

High Frequency (HF) Welders

Thermatool is the world’s leading brand in induction welding equipment. With two decades of success in solid state technology, and over fifty years of process knowledge, Thermatool solid state high frequency welders are the most advanced, reliable, field-proven welders available in the world today. Thermatool solid state welding units are designed to handle load fluctuations,https://www.inductothermgroup.com/products/high-frequency-hf-welders/...

LEARN MORE »

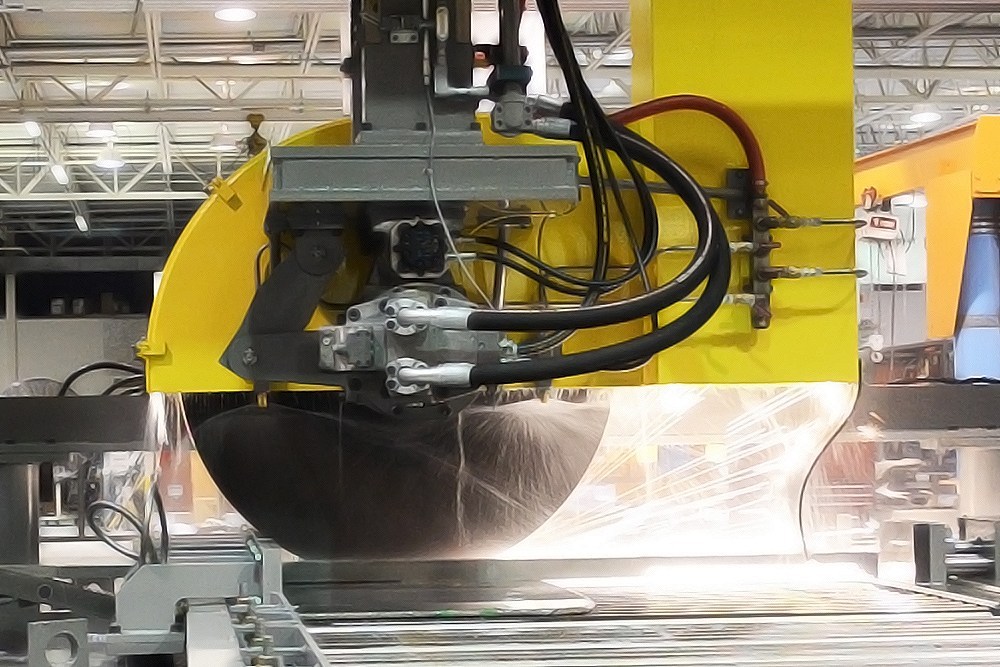

Savage Saws™ Brand Saws

Savage Saws™ saws are known for cutting the world’s most high performance, difficult to cut alloys. Servicing the aerospace, automotive, super alloy, and specialty material markets, Savage Saws™ provides precise and repeatable cut quality, in a lean manufacturing capable package....

LEARN MORE »

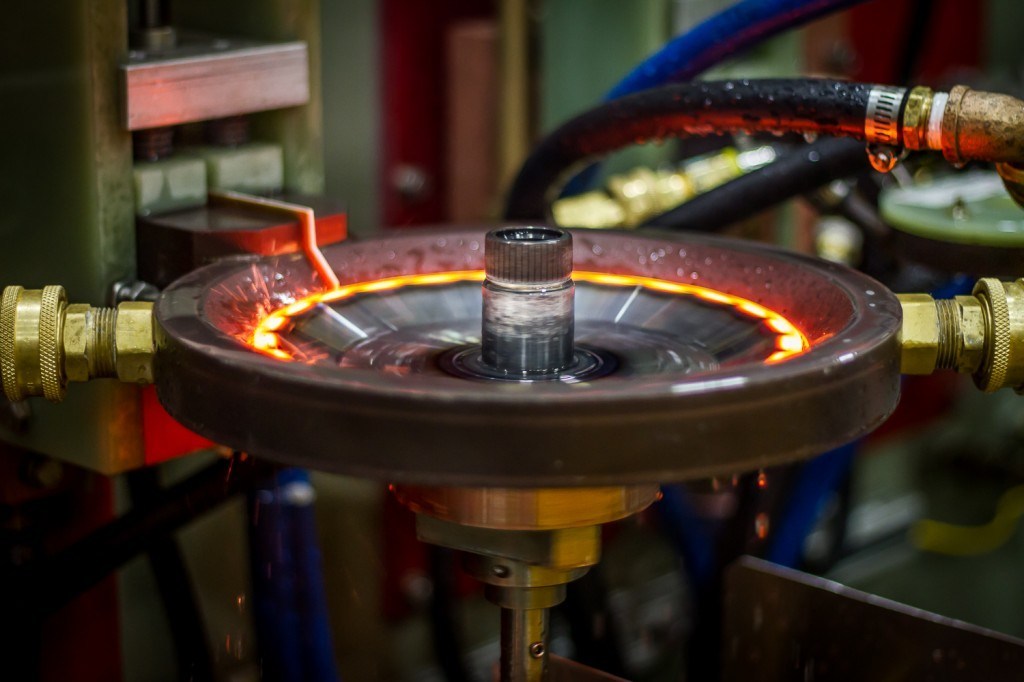

Line Frequency Systems for Shrink Fitting

IROSS™ Line Frequency Systems contain flux concentrators that utilize patented technology for yielding superior temperature uniformity. These units are used in a wide variety of applications, including shrink fitting for shafts and gears, pipe-end annealing, preheat for welding, camshaft gear assembly, crankshaft gear assembly, and shrink fitting of large differential gears....

LEARN MORE »

Vacuum Heat Treatment and Brazing Furnaces (VHT)

Vacuum heat treatment is a well-established practice in the aerospace (both OEM and repair), land-based turbine, automotive and tool industries. Controlled thermal processing of components is carried out in a vacuum environment to eliminate the deleterious effects of the charge reacting with the gases present in the air....

LEARN MORE »

Induction Skull Melting Furnaces (ISM)

Consarc offers Induction Skull Melting (ISM) furnaces which is a method of melting metals in a segmented water-cooled copper vessel while under vacuum or controlled atmosphere using an induction coil. Consarc ISM furnaces provide superior chemical and thermal homogeneity when compared to more traditional methods of melting reactive materials such as arc skull casting....

LEARN MORE »

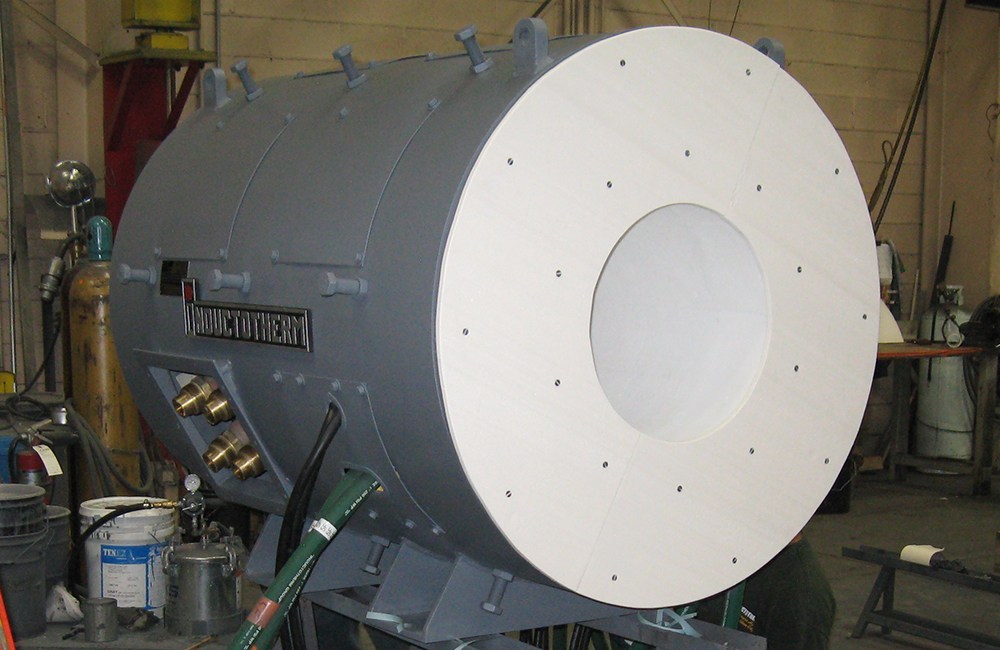

Vacuum Arc Remelting Furnaces (VAR)

VAR Furnaces are used for melting material that have already been melted and cast into electrodes that are near their full packing density. Consarc utilizes fully computerized controls to optimize reproducibility and ease of operation. Custom furnaces in laboratory scale or for the production of unusual geometric configurations are available upon request....

LEARN MORE »

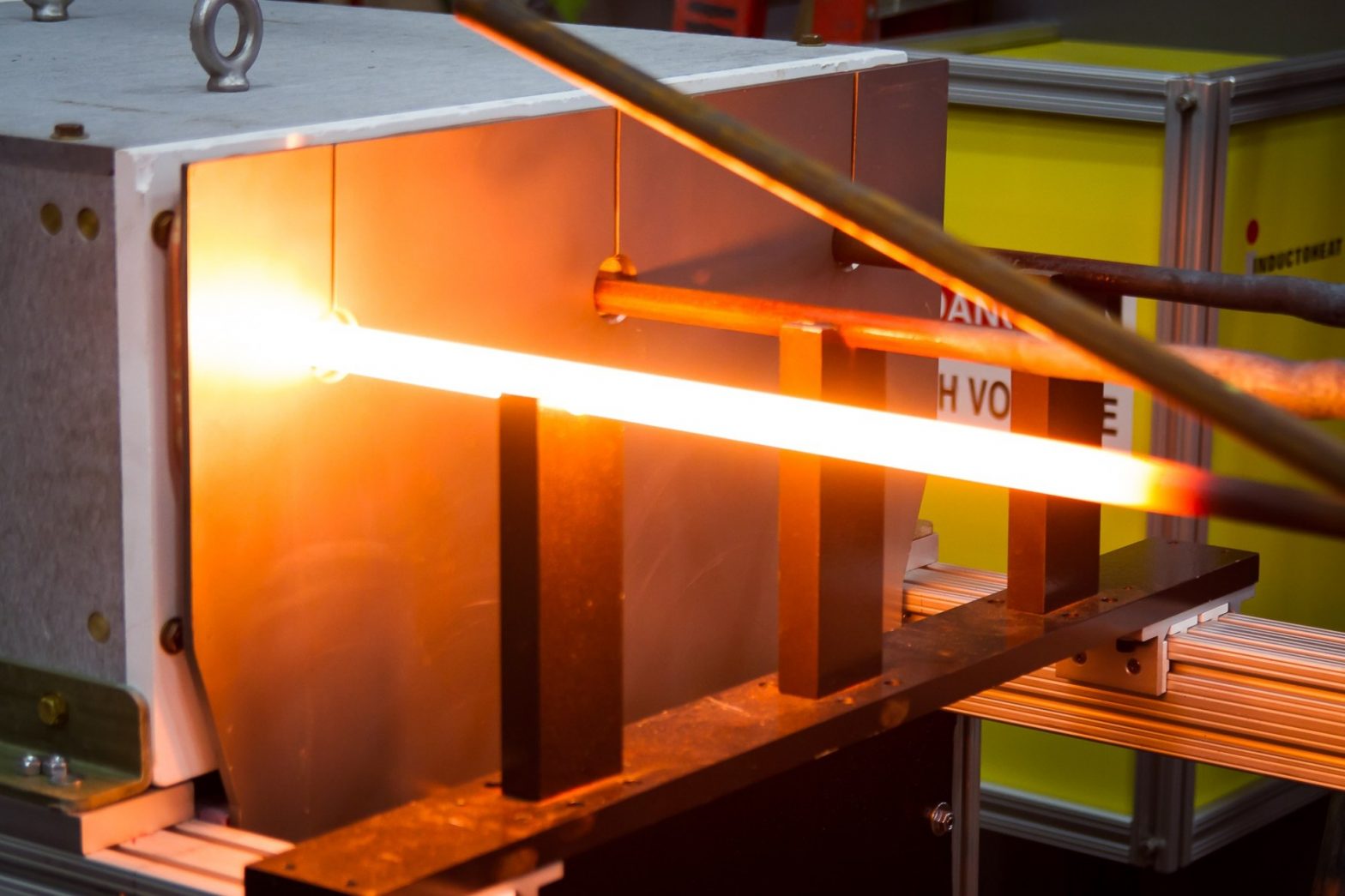

Single and Multi-Wire Induction Heating Systems

By improving efficiency and reducing energy costs, induction heating puts energy savings directly into your product. Radyne brand wire, rod and cable systems—available in both standard and custom designs—are built for a broad range of applications including spring wire, steel hardening and tempering, coating, annealing, and preheating for extrusion. Market demand for a quality finishhttps://www.inductothermgroup.com/products/single-and-multi-wire-induction-heating-systems/...

LEARN MORE »