Processes

Pipe and Tube Production

THE APPLICATION OF HEAT is often key to many manufacturing processes, such as welding, cutting, bending, shaping, fitting and sealing. Inductotherm Group companies consistently push the limits of design and implementation—giving the tube and pipe industry access to breakthroughs in high frequency welding and heat treating equipment, as well as power supplies, high-speed cutting machines and the most technologically advanced engineered structural-line equipment available today.

Related Resources

Pipe and Tube Production

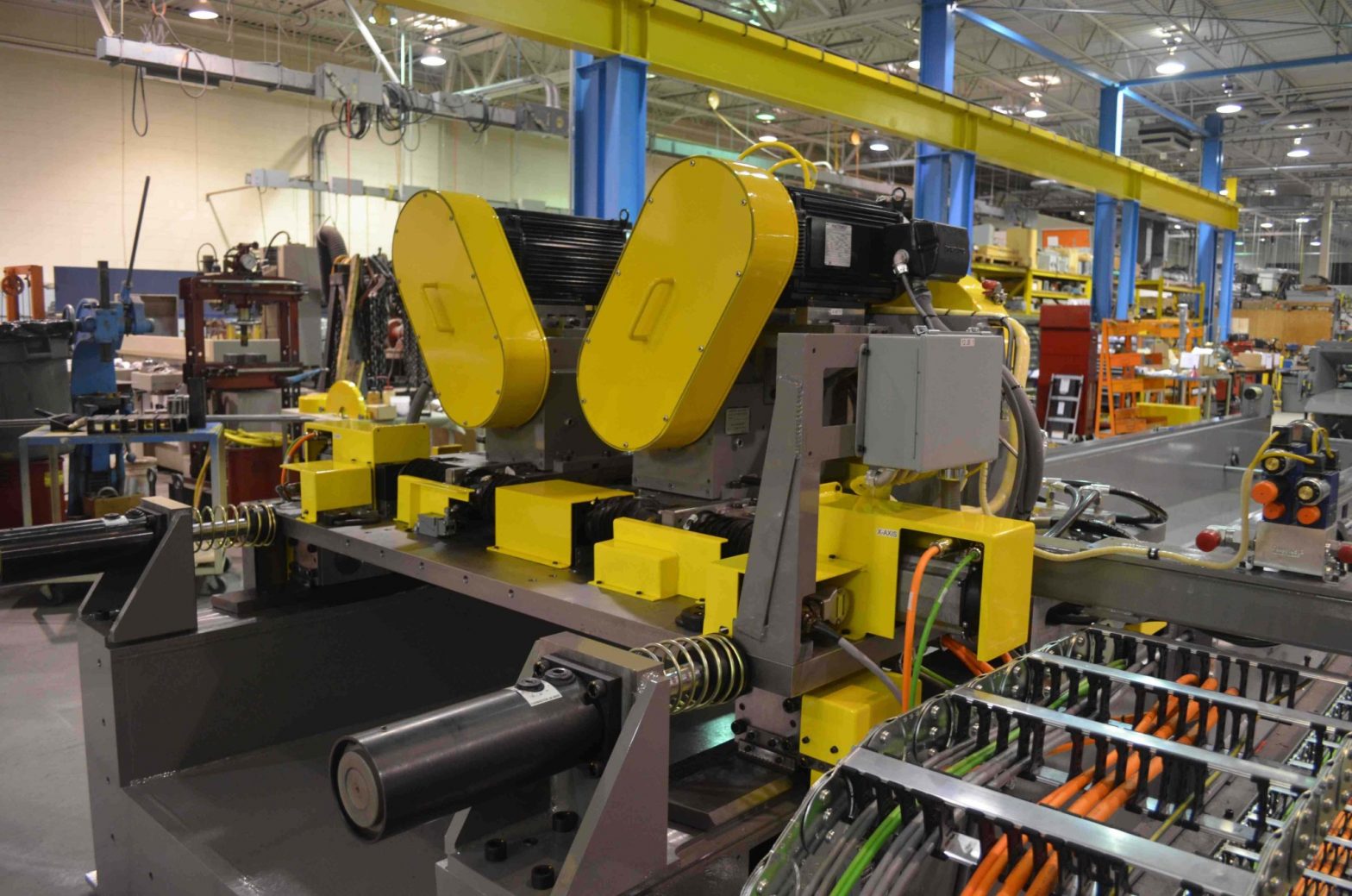

Flying Saws

Inductotherm Group companies offer a range of flying cold and friction saws to meet your tube and pipe cutting requirements. Alpha flying cold saws provide a near burr-free cut. Both single and multiple head designs are available for small or large product, or product which is reshaped into squares or rectangles. Blade surface speed ishttps://www.inductothermgroup.com/products/flying-saws/...

LEARN MORE »

High Frequency (HF) Welders

Thermatool is the world’s leading brand in induction welding equipment. With two decades of success in solid state technology, and over fifty years of process knowledge, Thermatool solid state high frequency welders are the most advanced, reliable, field-proven welders available in the world today. Thermatool solid state welding units are designed to handle load fluctuations,https://www.inductothermgroup.com/products/high-frequency-hf-welders/...

LEARN MORE »

High Speed Flying Shears

Alpha® flying shears are the fastest, most efficient and accurate tube cutting systems available in the world today. Alpha flying shears provide a patented double-cut die set which enables producers to cut dimple-free, ready for market products directly off the mill. Inductotherm Group companies offers a full range of Alpha flying shears for nearly allhttps://www.inductothermgroup.com/products/high-speed-flying-shears/...

LEARN MORE »

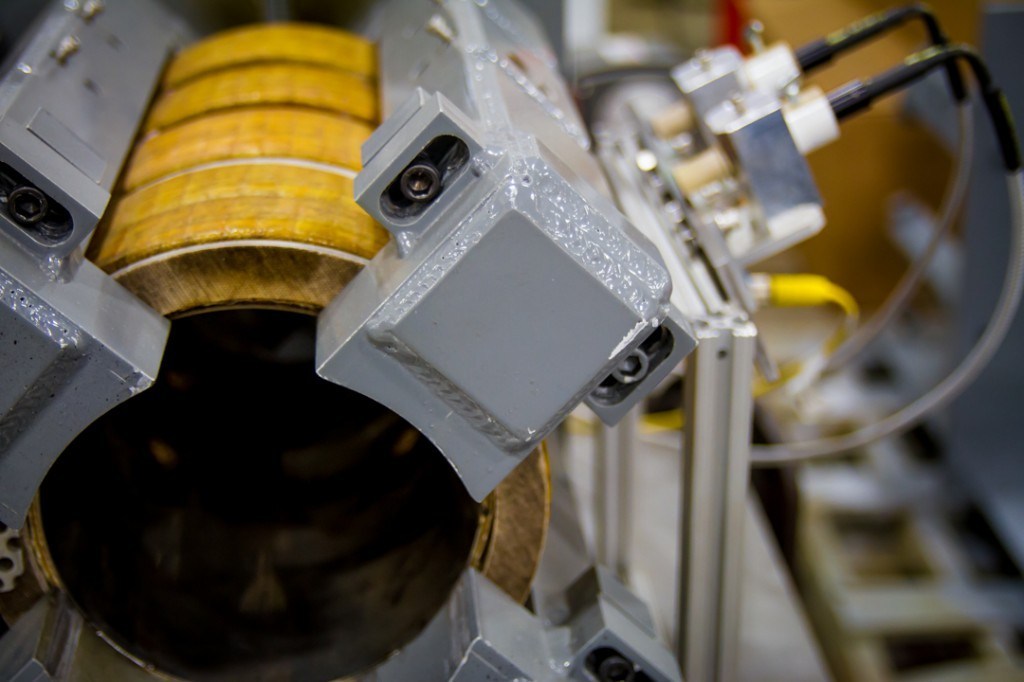

Induction Pipe Heaters with Flux Manager® Coil

iROSS™ Fluxmanager® Pipe-End Heating Units are designed for heating a variety of tubular products. These systems utilize patented Fluxmanager® induction heat treatment technology that yields superior temperature uniformity compared to conventional medium frequency designs....

LEARN MORE »

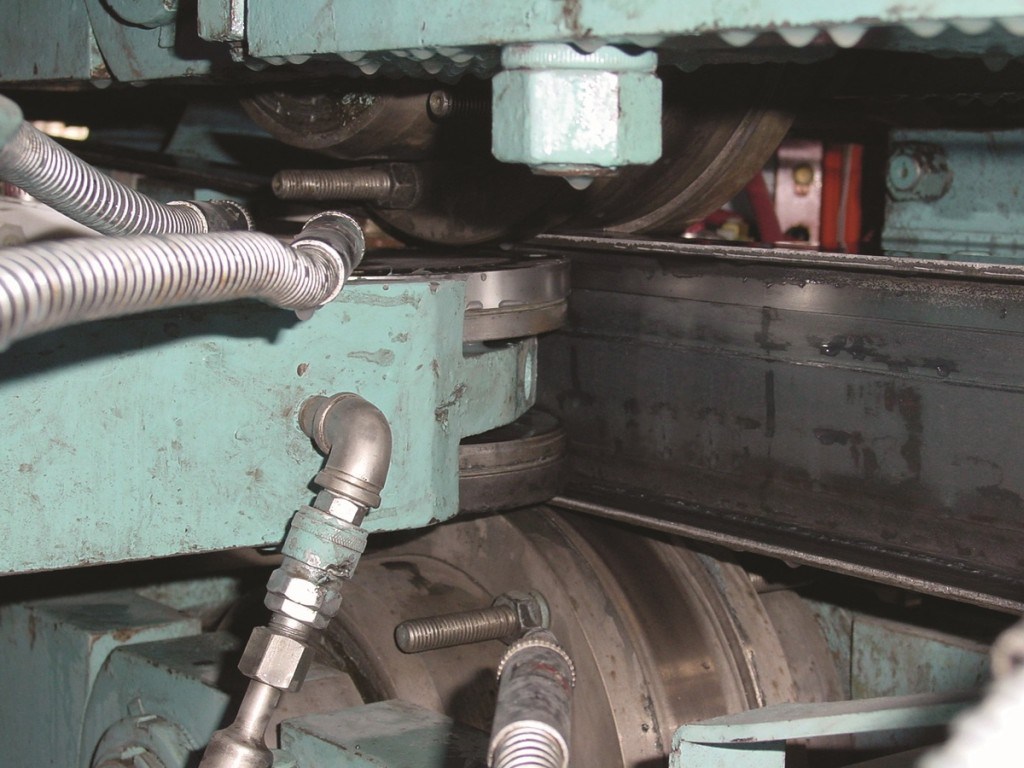

Line Frequency Systems for Shrink Fitting

IROSS™ Line Frequency Systems contain flux concentrators that utilize patented technology for yielding superior temperature uniformity. These units are used in a wide variety of applications, including shrink fitting for shafts and gears, pipe-end annealing, preheat for welding, camshaft gear assembly, crankshaft gear assembly, and shrink fitting of large differential gears....

LEARN MORE »

Pipe Bending and Forming Heaters

For many metal forming processes, induction heating delivers the precisely controlled heat that allows for efficient and accurate forming and bending of rod, tube, bar and other metals. Inductotherm Group companies manufacture a variety of specialized heating equipment for pipe bending and forming under the Radyne brand. Radyne Pipe Heat Bending Systems are fully integrated,https://www.inductothermgroup.com/products/pipe-bending-and-forming-heaters/...

LEARN MORE »

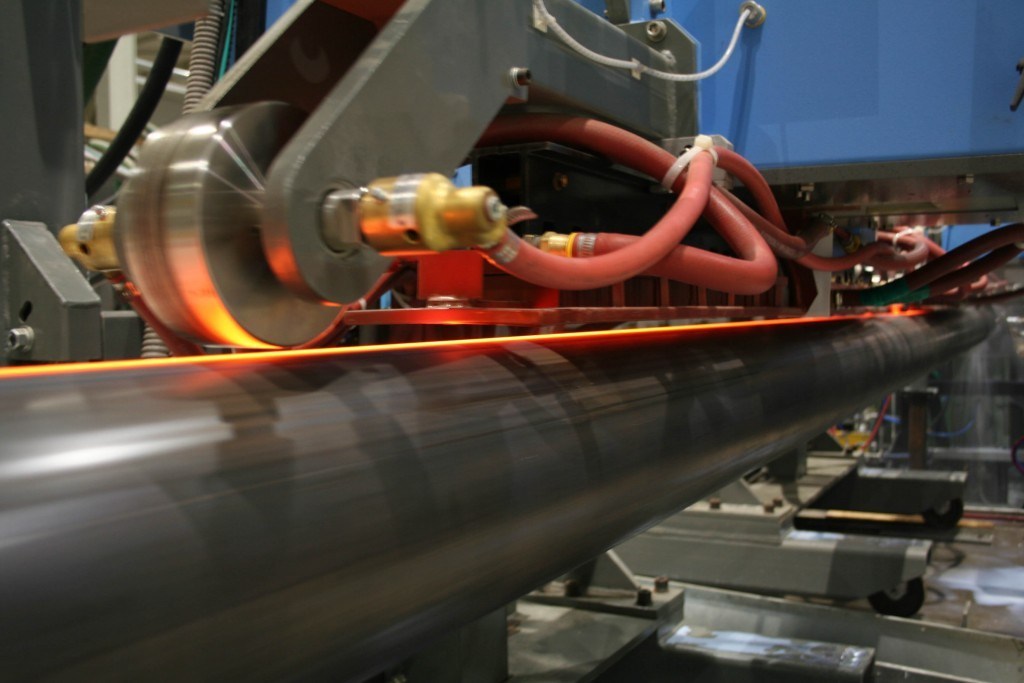

Quench and Temper Bar and Tube Equipment

Thermatool™ Quench and Temper lines can process 2, 5, 10, 15, 20 or 30 tons per hour for Austenitizing, Quench and Temper utilizing induction, gas, or electric furnaces coupled with the Thermatool™ Precision Quench™. Thermatool™ Quench and Temper lines feature Solid State Induction power supplies and a patented high-technology modular PrecisionSlot™ Quench. To be effective, these lines require the abilityhttps://www.inductothermgroup.com/products/quench-and-temper-bar-and-tube-equipment/...

LEARN MORE »

Savage Saws™ Brand Saws

Savage Saws™ saws are known for cutting the world’s most high performance, difficult to cut alloys. Servicing the aerospace, automotive, super alloy, and specialty material markets, Savage Saws™ provides precise and repeatable cut quality, in a lean manufacturing capable package....

LEARN MORE »

Tube Heaters/Seam Annealers

Many Inductotherm Group companies manufacture Thermatool brand seam annealing/normalizing systems for the tube and pipe industry. These highly efficient systems provide rigorous quality control and ensure process repeatability with their continuous temperature monitoring, required by all API pipe producers to prove that critical process temperatures have been reached during each shift. Powered by VIP™ Serieshttps://www.inductothermgroup.com/products/tube-heaters-seam-annealers/...

LEARN MORE »

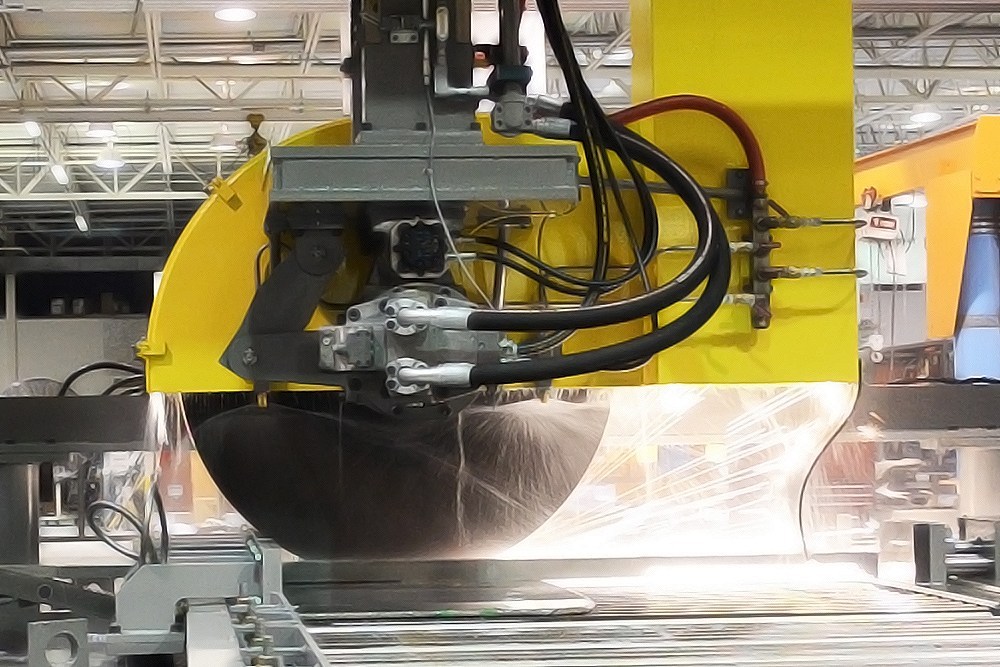

Welding Lines for I-Beam

Patented in 1970, Thermatool™ Engineered Structural Section Lines have been field proven again and again for structural HF Welded beam production. With the advent of new steel chemistries and improved flat rolled steel technologies, HF Welded Engineered Structural Section production is meeting ever-growing infrastructure demands by providing innovative engineered solutions to structural design problems. An alternativehttps://www.inductothermgroup.com/products/welding-lines-for-i-beam/...

LEARN MORE »