Industries

Dental and Medical

There was a time when many artificial teeth were made of gold. For good reasons. Gold is inert and non-corrosive. It does not cause tissue reactions; it does not negatively affect gums and other soft tissue. Eventually, because gold is also a relatively soft metal, it was replaced in dentistry with alloys that have similar properties but are much more durable.

Alloys and specialty metals are used significantly in medical devices as well. While multiple varieties of stainless steel were the predominant metals in the earliest days of the medical device industry, metallurgists continued to develop specialty alloys to address very specific device manufacturing needs.

Inductotherm Group companies are very familiar with the uses of element metals and alloys across the dental and medical device industries, and highly knowledgeable about the thermal processing equipment needed in manufacturing everything from dental implants to pacemakers.

Related Resources

Select a Process

Induction Melting Furnaces

Inductotherm brand coreless melting furnaces provide superior performance and outstanding durability for all your melt shop needs, regardless of the size of your foundry. Inductotherm Group companies offer a range of furnace sizes from small induction melting furnaces that meet the demanding requirements of investment casters, specialty foundries and the precious metals industry, to heavyhttps://www.inductothermgroup.com/products/induction-melting-furnaces/...

LEARN MORE »

Flying Saws

Inductotherm Group companies offer a range of flying cold and friction saws to meet your tube and pipe cutting requirements. Alpha flying cold saws provide a near burr-free cut. Both single and multiple head designs are available for small or large product, or product which is reshaped into squares or rectangles. Blade surface speed ishttps://www.inductothermgroup.com/products/flying-saws/...

LEARN MORE »

High Frequency (HF) Welders

Thermatool is the world’s leading brand in induction welding equipment. With two decades of success in solid state technology, and over fifty years of process knowledge, Thermatool solid state high frequency welders are the most advanced, reliable, field-proven welders available in the world today. Thermatool solid state welding units are designed to handle load fluctuations,https://www.inductothermgroup.com/products/high-frequency-hf-welders/...

LEARN MORE »

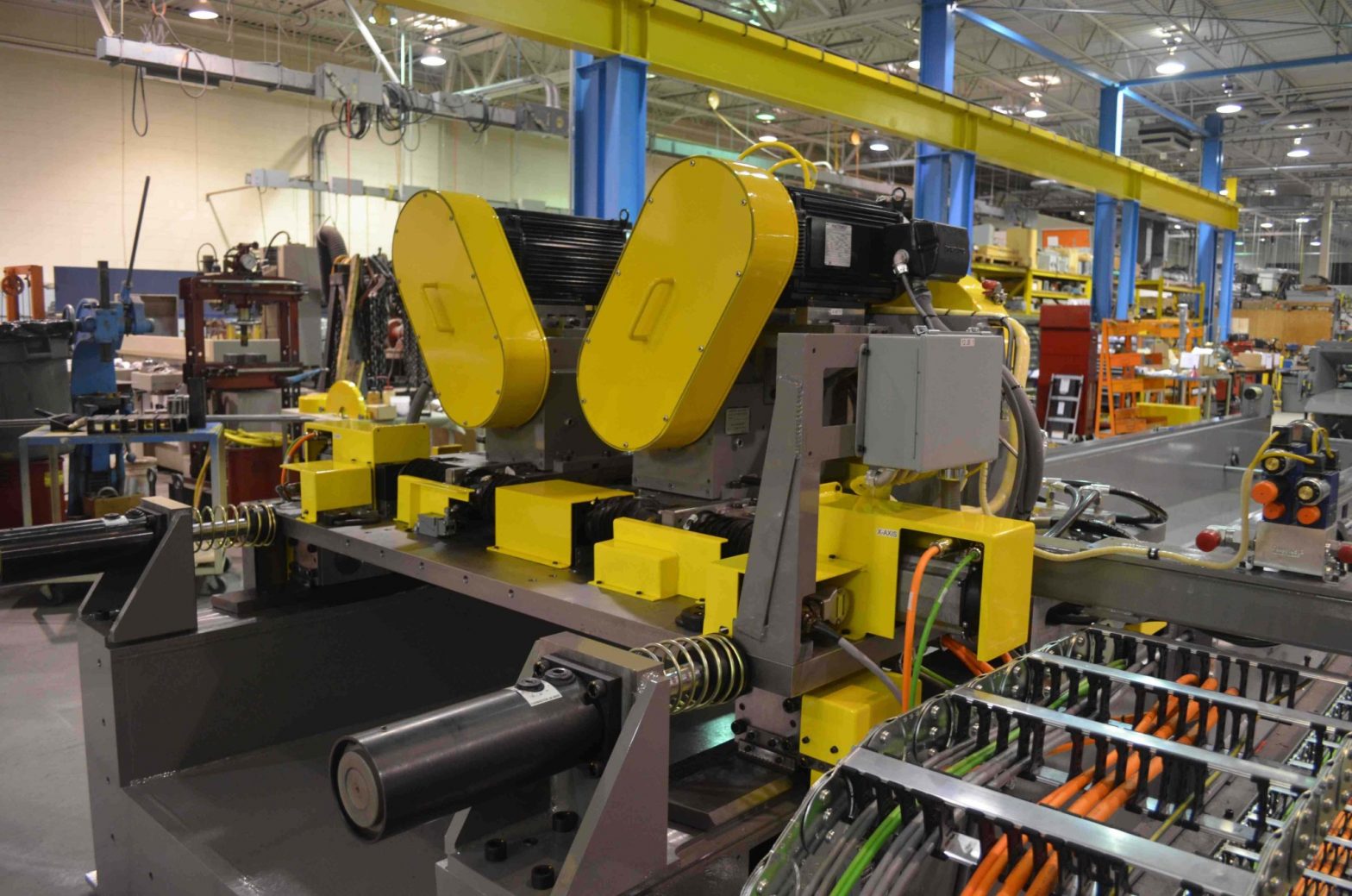

High Speed Flying Shears

Alpha® flying shears are the fastest, most efficient and accurate tube cutting systems available in the world today. Alpha flying shears provide a patented double-cut die set which enables producers to cut dimple-free, ready for market products directly off the mill. Inductotherm Group companies offers a full range of Alpha flying shears for nearly allhttps://www.inductothermgroup.com/products/high-speed-flying-shears/...

LEARN MORE »

Induction Skull Melting Furnaces (ISM)

Consarc offers Induction Skull Melting (ISM) furnaces which is a method of melting metals in a segmented water-cooled copper vessel while under vacuum or controlled atmosphere using an induction coil. Consarc ISM furnaces provide superior chemical and thermal homogeneity when compared to more traditional methods of melting reactive materials such as arc skull casting....

LEARN MORE »

Vacuum Arc Remelting Furnaces (VAR)

VAR Furnaces are used for melting material that have already been melted and cast into electrodes that are near their full packing density. Consarc utilizes fully computerized controls to optimize reproducibility and ease of operation. Custom furnaces in laboratory scale or for the production of unusual geometric configurations are available upon request....

LEARN MORE »

Vacuum Induction Melting Furnaces (VIM)

Consarc brand equipment includes a variety of Vacuum Induction Melting (VIM) furnaces, including Electrode VIM systems, Master Alloy VIM systems, and small R&D systems. A wide variety of configurations are available to match customer requirements....

LEARN MORE »