Article | June 7th, 2019

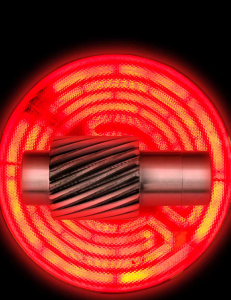

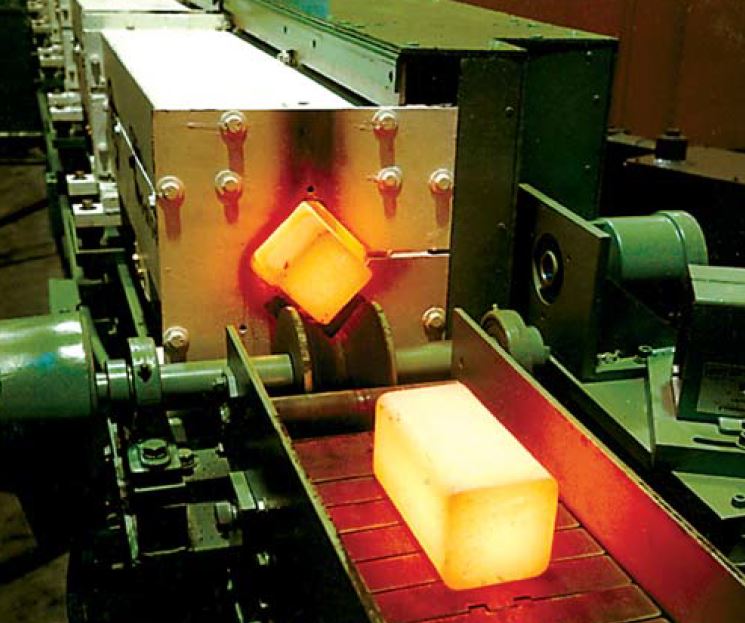

Induction Heating Serves Todays Forging Industry

Induction heating can offer benefits to forgers in certain applications. Process and design requirements for suitable applications are examined, as are common types of induction heating configurations.

By Dr. Valery Rudnev

There are many ways to heat metal parts, including the use of induction heaters, gas-fired furnaces, infrared heaters, electric and fuel-fired furnaces, etc. In the past three decades, heating by induction has become more popular because of its ability to create high heat intensity quickly and within the heated workpiece. These properties, in turn, result in low process cycle times

(high productivity) as well as repeatable quality. Induction heating is also more energy efficient and inherently more environmentally friendly than most other heat sources, including gas-fired furnaces. Any smoke and fumes that may occur because of residual lubricants or other surface contaminants can be easily removed. A considerable reduction of heat exposure is another factor that contributes to the environmental friendliness of the induction heaters.