Article | June 7th, 2019

Implications of induction hardening

By Dr. Valery Rudnev

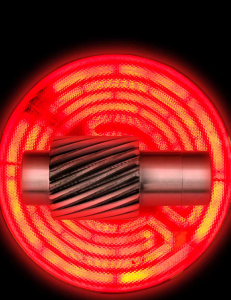

One of the most common applications of induction heat treatment is the hardening of steels, cast irons, and powder metallurgy materials. Among other workpieces, such components as camshafts, crankshafts, gears, transmission shafts, ball studs, pins, working surfaces of tools, and many others are commonly hardened using electromagnetic induction developing an attractive blend of engineering properties.

A typical induction hardening (IH) procedure involves heating the alloy to the austenitizing temperature range, holding it (if necessary) at a temperature for a period long enough for the completion of the formation of a fully or predominantly austenitic structure and then rapidly cooling/quenching it below the Ms critical temperature. Rapid cooling allows replacement of the diffusion-dependent transformation of austenite by diffusion-less shear-type transformation, producing a much harder constituent called martensite.