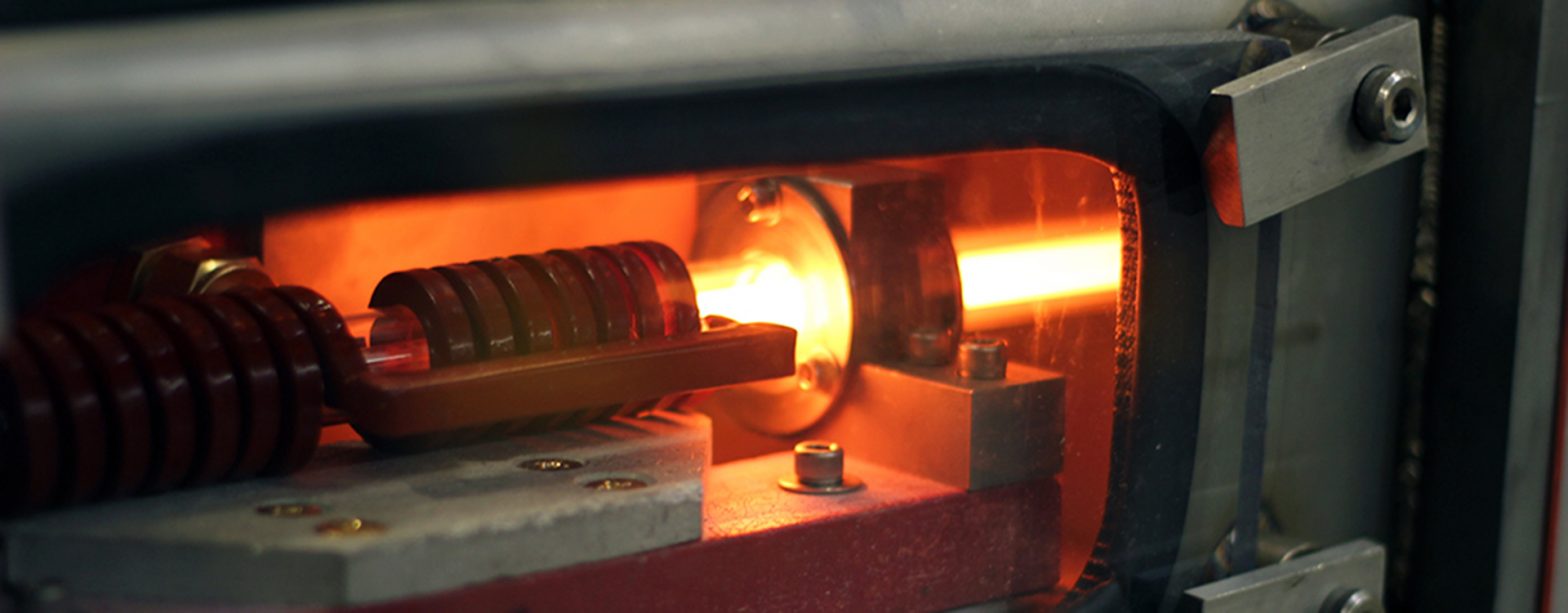

Radyne products are built on a foundation of innovation. Spanning from hardening and tempering processes to brazing and annealing applications, Radyne products have a lineage of performance, flexibility and durability, that deliver a consistent, high quality part every time.

Processes

Brazing and Soldering

Induction Brazing and Soldering Systems

Radyne brazing and soldering systems offer permanent and strong metal-to-metal joints with three primary benefits. Flexibility: Brazing is the joining of metals by use of heat and filler metals. As the most versatile method of joining metals, brazed joints are strong, ductile, easy and quick to make, suited to the joining of dissimilar and similarhttps://www.inductothermgroup.com/products/induction-brazing-and-soldering-systems/...

LEARN MORE »Heating and Heat Treating

General Heat Treat Systems

Radyne brand heat treatment systems offer flexible, robust induction heat treating that can be effortlessly integrated into your production ecosystem. Radyne heat treat systems include a full line of scanners and pop-ups to handle large and small parts, from parts under an ounce and shorter than an inch to parts over 5000 lbs. in weighthttps://www.inductothermgroup.com/products/general-heat-treat-systems/...

LEARN MORE »

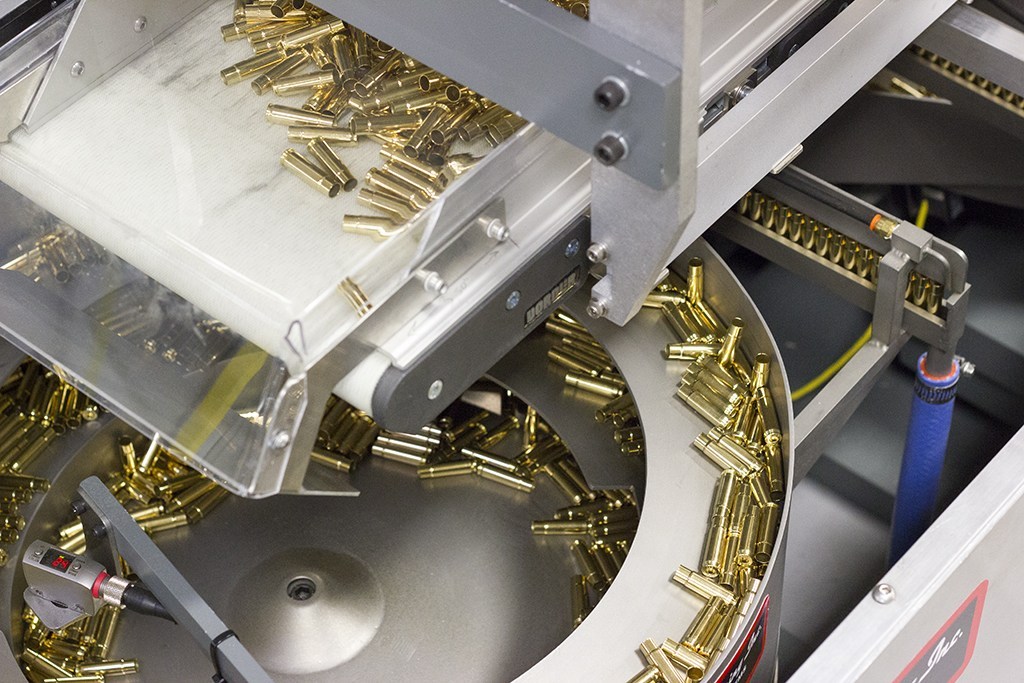

Munitions and Ammunition Annealing and Bonding Systems

Radyne brand ammunition annealing and bonding systems are used to make bullets for law enforcement and military applications, as well as for the hunting and shooting enthusiast. Radyne brand has a well-established history of designing induction heating equipment that is used for heat treating and forming shells to create specialized fragmentation patterns, penetrating characteristics, andhttps://www.inductothermgroup.com/products/munitions-and-ammunition-annealing-and-bonding-systems/...

LEARN MORE »Pipe Coating

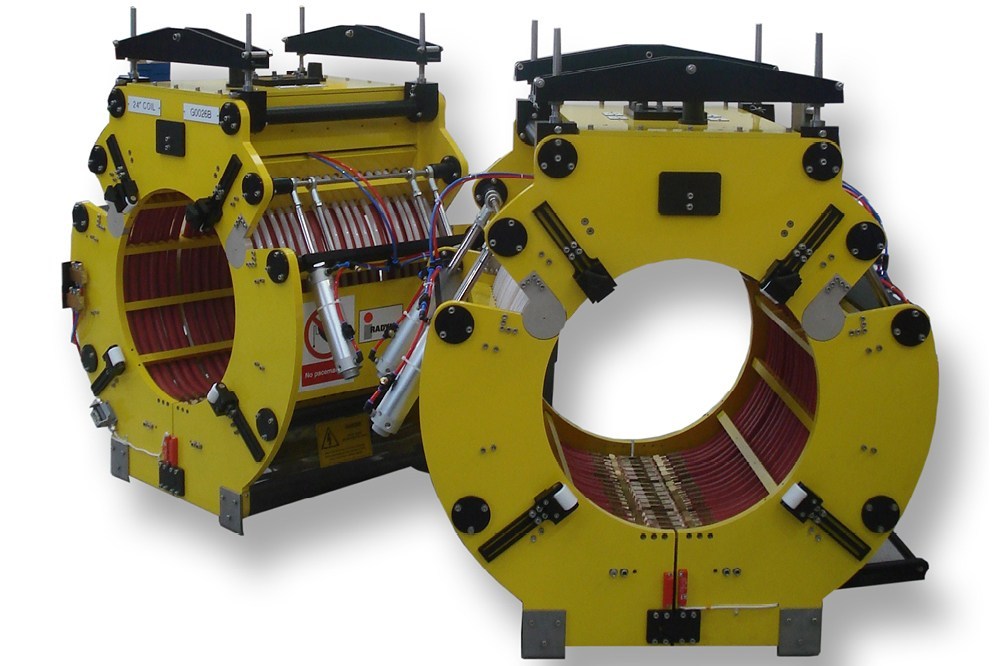

Merlin™ Coating Systems

Proven on several international pipeline projects, Radyne Merlin™ Pipe Coating Systems deliver the most efficient means for the heating and the coating of field joints by addressing both operations simultaneously. This is a major benefit to offshore pipe laying organizations because they can count on the Merlin system for reduced field joint processing cycle times,https://www.inductothermgroup.com/products/merlin-coating-systems/...

LEARN MORE »

Offline Pipe and Tube Coating Systems

Inductotherm Group companies manufacture a range of specialized, Radyne brand induction heating systems for pipe heating and coating processes in both onshore and offshore applications. Onshore-based applications include line pipe preheating prior to coating and pie end heating. Offshore systems focus on field joint processing, with a series of induction systems utilized for the heatinghttps://www.inductothermgroup.com/products/offline-pipe-and-tube-coating-systems/...

LEARN MORE »Pipe and Tube Production

Pipe Bending and Forming Heaters

For many metal forming processes, induction heating delivers the precisely controlled heat that allows for efficient and accurate forming and bending of rod, tube, bar and other metals. Inductotherm Group companies manufacture a variety of specialized heating equipment for pipe bending and forming under the Radyne brand. Radyne Pipe Heat Bending Systems are fully integrated,https://www.inductothermgroup.com/products/pipe-bending-and-forming-heaters/...

LEARN MORE »Wire Production

Single and Multi-Wire Induction Heating Systems

By improving efficiency and reducing energy costs, induction heating puts energy savings directly into your product. Radyne brand wire, rod and cable systems—available in both standard and custom designs—are built for a broad range of applications including spring wire, steel hardening and tempering, coating, annealing, and preheating for extrusion. Market demand for a quality finishhttps://www.inductothermgroup.com/products/single-and-multi-wire-induction-heating-systems/...

LEARN MORE »