Inductotherm is the worldwide leader in induction technology. Inductotherm equipment are the most advanced melting, heating, holding, and pouring systems for virtually all metal and material processing including, gray and ductile iron, steel, copper and copper-based alloys, aluminum, zinc, reactive metals, precious metals, silicon, and graphite heating; as well as numerous other special applications. Inductotherm brand equipment also includes a complete line of induction equipment for melting, heating, coating, galvanizing, and galvanealing on a continuous basis, primarily for the steel industry. With proven technology for every melt shop need, only Inductotherm can offer you efficient, reliable and effective systems to give you the competitive edge.

Processes

Billet and Bar Forging

Rail and Mill Roll Hardening

Mill Roll Hardening Systems are becoming increasingly popular with the expanding development of cold mills which subject the rolls to high stresses. For the surface heating of steel parts, induction heating is considered to be the application best suited for this. Induction heating has many applications and is especially effective in hardening rolling mill rolls. Railhttps://www.inductothermgroup.com/products/rail-and-mill-roll-hardening/...

LEARN MORE »

Slab, Bloom and Transfer Bar Heaters

Our high-power density Slab, Bloom and Transfer Bar Heaters provide efficient and cost-effective technologies to bring surfaces to the optimal temperatures required for forming, rolling or forging. Metals which are susceptible to oxidation and scale formation such as titanium, if heated above certain temperatures, can be accurately heated using induction heating, thus increasing yield andhttps://www.inductothermgroup.com/products/slab-bloom-and-transfer-bar-heaters/...

LEARN MORE »Melting, Holding and Pouring

ARMS® (Automated Robotic Melt Shop Systems)

Inductotherm Group companies are the first to develop and manufacture an innovative automated robotic melt shop system, called the ARMS™ System. The ARMS System replaces the furnace operator on the open melt deck with a foundry robot that has integrated charging, slag removal, tool handling and remote viewing systems. This allows the furnace operator tohttps://www.inductothermgroup.com/products/arms-automated-robotic-melt-shop-systems/...

LEARN MORE »

Automated Pouring Systems

Inductotherm brand automated pouring systems for foundries and melt shops are designed for maximum productivity. They provide the higher levels of pouring accuracy required to eliminate quality robbing under-pours and metal wasting over-pours....

LEARN MORE »

Induction Holding Furnaces

Inductotherm Group companies manufacture two types of advanced holding systems: Channel furnaces and Mini-Heel™ furnaces. Both offer true volume flexibility for continuous and batch duplexing, and can maintain a continuous supply of metal ready to pour 24 hours a day, 7 days a week....

LEARN MORE »

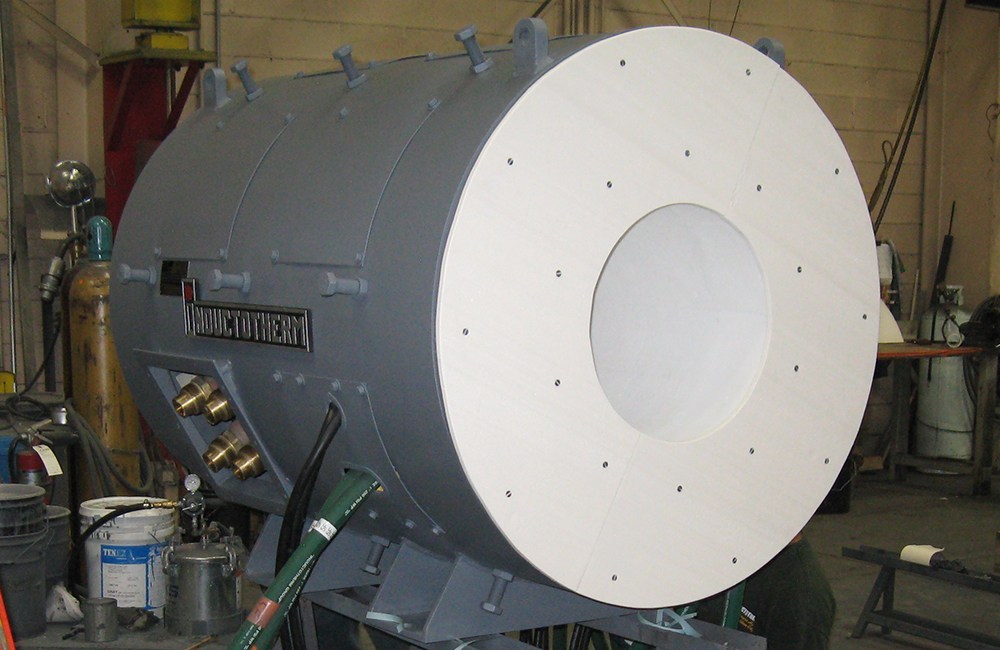

Induction Melting Furnaces

Inductotherm brand coreless melting furnaces provide superior performance and outstanding durability for all your melt shop needs, regardless of the size of your foundry. Inductotherm Group companies offer a range of furnace sizes from small induction melting furnaces that meet the demanding requirements of investment casters, specialty foundries and the precious metals industry, to heavyhttps://www.inductothermgroup.com/products/induction-melting-furnaces/...

LEARN MORE »Strip Heating and Coating

Galvanizing Pots

As the world leader in induction melting technology, Inductotherm Group companies design and manufacture the industry’s most advanced systems for working with zinc and zinc alloys. We offer a full line of high performance galvanizing pots for coating applications, including specially-designed coating pots, pre-melting pots and emergency holding pots....

LEARN MORE »

Strip Heaters

Inductotherm brand equipment brings the world’s most advanced induction heating technology to continuous annealing and coating lines. Equipment includes in-line strip annealing systems, strip heaters, edge heaters, galvanneal heaters, boost heaters, tin reflow systems, paint dryers and anti-fingerprint systems. By adding induction technology to their process lines, customers can significantly reduce yield losses and increasehttps://www.inductothermgroup.com/products/strip-heaters/...

LEARN MORE »