Banyard specializes in non-ferrous induction heating technology providing mains and low frequency heating solutions for Aluminium, Brass, Copper and exotic alloys for both sawn and sheared billets.

Processes

Billet and Bar Forging

Boost Induction Heaters

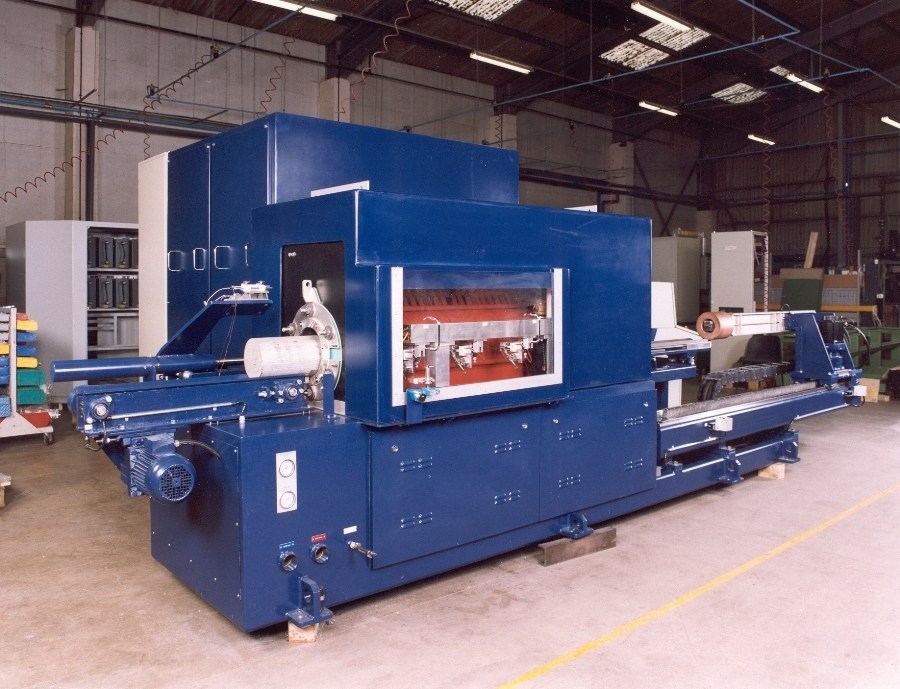

The Banyard Boost Induction Heater has established itself as a low cost, highly compact, induction boost taper heater for use with either gas or induction pre-heaters. Using a servo-controlled billet positioning system to control both accuracy and speed, the Boost Induction Heater enables extruders to boost billet temperature and line speed, with a consequent increasehttps://www.inductothermgroup.com/products/boost-induction-heaters/...

LEARN MORE »

Horizontal Billet Heaters (nonferrous)

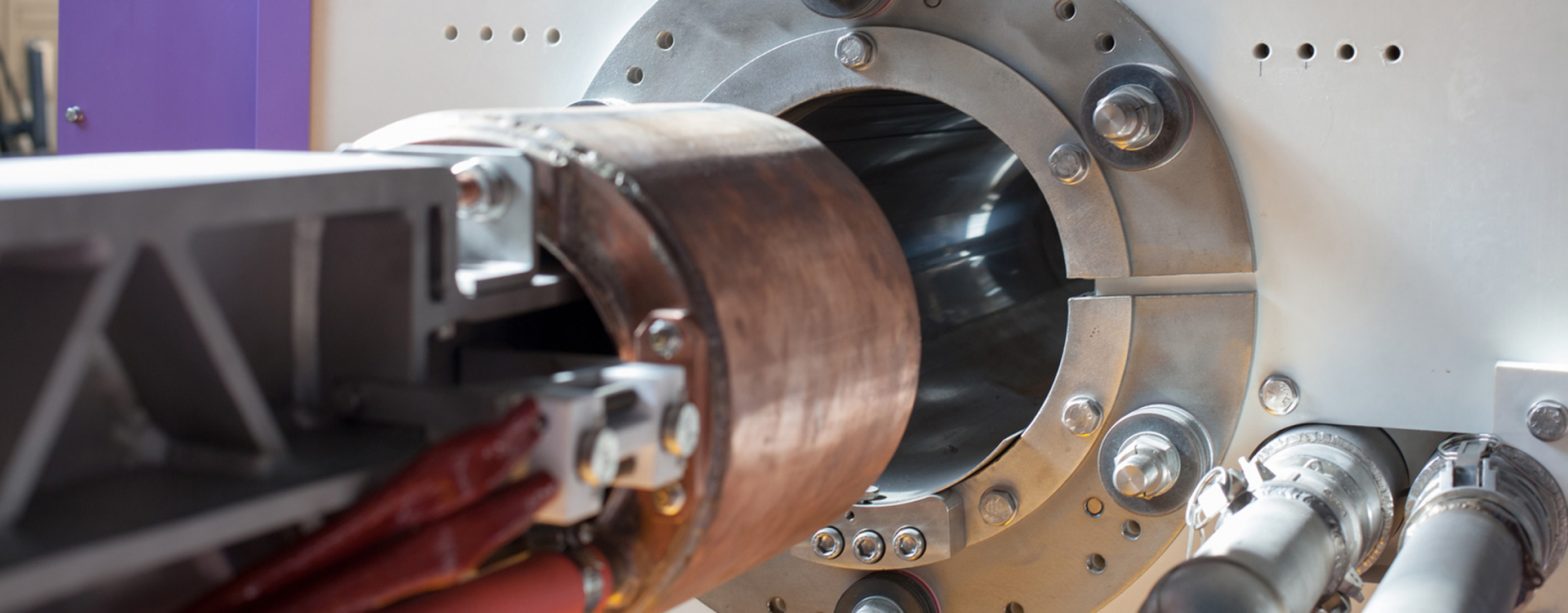

Inductotherm Group’s development of phase synchronized multi-zone power modules has made accurate static taper heating possible. A static taper heating coil is divided into a number of independently controlled zones, each with its own thermocouples executing its own power profile. This enables optimum temperature control. Synchronization of the modules ensures that there is a seamlesshttps://www.inductothermgroup.com/products/horizontal-billet-heaters-nonferrous/...

LEARN MORE »

Vertical Billet Heaters

Banyard Vertical Steel Induction (VSI) systems have been designed for the precise vertical induction heating of solid or pierced billets and tubes. These systems heat billet diameters from 150mm to 460mm, and lengths from 300mm to 1500mm. Benefits include better temperature distribution, ability to vary the temperature profile along the billet length, and no billethttps://www.inductothermgroup.com/products/vertical-billet-heaters/...

LEARN MORE »

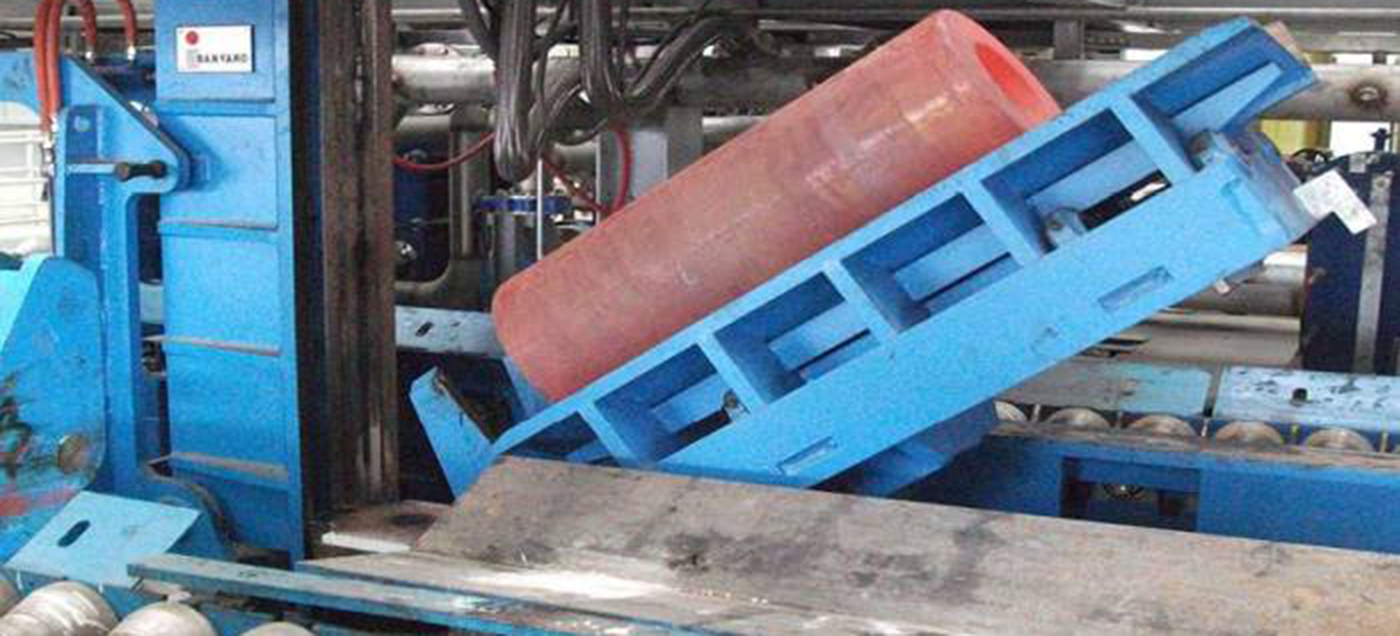

Zero Friction Billet Heaters

Banyard brand induction heating systems feature special mechanical handling technology designed specifically to address the needs of the aluminium micro-tubing sector. The Banyard solution enables aluminum billet transport with virtually zero friction. This is achieved by effectively minimizing the area of contact with the billet at all stages of the process. Smooth movement is alsohttps://www.inductothermgroup.com/products/zero-friction-billet-heaters/...

LEARN MORE »